Menu

Fechar

- Who we are

- Success stories

- Our solutions

Our solutions

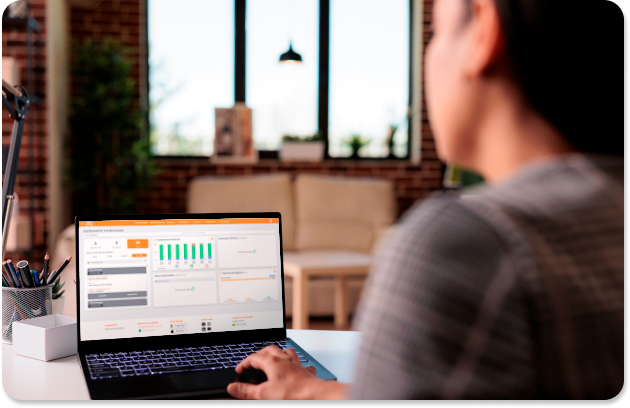

Discover the solutions that are revolutionizing the market with efficient management, ensuring savings and efficiency for your company.

Interested in our services?

Discover the solutions that are revolutionizing the market with efficient management, ensuring savings and efficiency for your company.

- Data intelligence

- Blog

- Resources

-

Definitive Guide to Energy Efficiency in SupermarketsDefinitive Guide to Energy Efficiency in Supermarkets

-

Definitive Guide to Energy Efficiency in SupermarketsDefinitive Guide to Energy Efficiency in Supermarkets

-

- Contact

- Who we are

- Success stories

- Our solutions

Our solutions

Discover the solutions that are revolutionizing the market with efficient management, ensuring savings and efficiency for your company.

Interested in our services?

Discover the solutions that are revolutionizing the market with efficient management, ensuring savings and efficiency for your company.

- Data intelligence

- Blog

- Resources

-

Definitive Guide to Energy Efficiency in SupermarketsDefinitive Guide to Energy Efficiency in Supermarkets

-

Definitive Guide to Energy Efficiency in SupermarketsDefinitive Guide to Energy Efficiency in Supermarkets

-

- Contact

Menu