Maintenance is a crucial pillar for the efficient operation of critical systems such as refrigeration and air conditioning in supermarkets. In this content, we will compare the approach most widely applied in large supermarket chains, Preventive Maintenance, and Condition-Based Maintenance (CBM). Although both aim to minimize failures, they have distinct characteristics that directly impact automation, monitoring, energy efficiency, and operational costs.

Similarities and Differences between Preventive and CBM

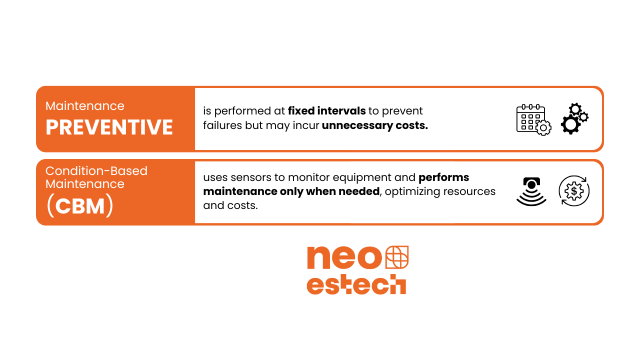

- Preventive Maintenance

- Definition: Performed at scheduled intervals, based on equipment usage time or operational cycle count.

- Avantage : Reduces the likelihood of unexpected failures.

- Limitation: Can be inefficient, as maintenance is not always needed, leading to additional costs and possible premature component wear.

- Condition-Based Maintenance (CBM)

- Definition: Uses sensors and monitoring technologies to assess equipment's operational conditions in real time, allowing maintenance to be performed only when necessary.

- Avantage : Avoids unnecessary maintenance and prevents unexpected failures, optimizing resources and improving predictability.

- Differentiator: Adapts to real operating conditions, ensuring greater precision in interventions.

Practical Examples: Impacts on Automation and Monitoring Systems

- Preventive Maintenance: A refrigeration system may undergo monthly inspections even without signs of wear. While effective in preventing major failures, this approach can result in unnecessary costs by replacing still-functional components.

- CBM: Temperature and pressure sensors constantly monitor compressor performance. Any deviation from expected parameters triggers automatic alerts, allowing technicians to intervene before the problem worsens. This automation reduces the risk of unexpected failures and increases efficiency.

Energy Consumption Reduction with CBM

The CBM approach directly contributes to energy efficiency. By monitoring variables such as overheating, pressure, and energy consumption, CBM identifies operational inefficiencies that could go unnoticed in a preventive maintenance routine.

Practical example: An overloaded compressor can consume up to 20% more energy. With CBM, this issue can be detected and corrected before waste significantly impacts costs.

Reduction of Labor Costs in Maintenance

Studies show that CBM can significantly reduce labor costs and unnecessary interventions. For example, an analysis performed at Companhia Siderúrgica de Tubarão showed that adopting CBM-aligned practices led to a reduction of up to 50% in annual labor costs for planned downtimes (ABM Proceedings).

Another study conducted by SciELO highlighted that the application of reliability-centered maintenance strategies, such as CBM, optimizes human resources by reducing unnecessary visits and increasing team efficiency (SciELO).

- Targeted Interventions: Teams are only called when there is evidence of anomalies, eliminating unnecessary visits.

- Operational Efficiency: Time spent on manual diagnostics is reduced, as CBM provides detailed real-time reports.

Conclusion

Although preventive maintenance still plays a role in certain contexts, CBM emerges as a more efficient and adaptable solution, especially in environments that rely on high-performance refrigeration and air conditioning systems. By reducing costs, optimizing energy consumption, and ensuring greater predictability, CBM represents the future of intelligent maintenance.

Ready to optimize your supermarket’s maintenance? Click here and Discover how NEO Estech and CBM can transform your operations and deliver sustainable results!