The integration of sensors in refrigeration and air conditioning systems is revolutionizing automation and monitoring in supermarkets. Modern sensors enable real-time tracking of operational conditions, increasing efficiency, preventing failures, and reducing operational costs. Let’s explore the benefits, functionality, and key types of sensors used in these systems.

Benefits of Automation with Sensors in Supermarkets

- 1. Continuous Monitoring:

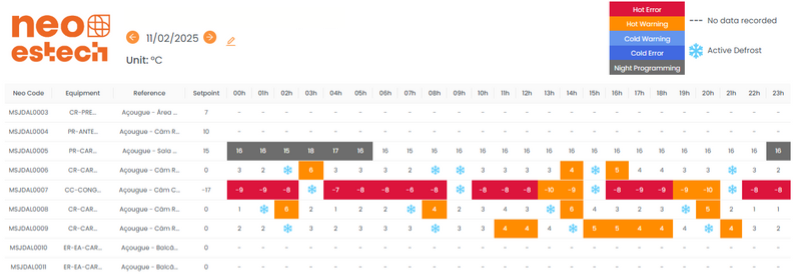

- o Sensors provide real-time data on critical variables such as temperature, humidity, pressure, and vibration.

- o This data helps detect anomalies before they lead to major failures.

- • Cost Reduction:

- o Early detection of problems reduces the need for corrective maintenance, which is more expensive and directly affects operations.

- o Improved energy efficiency lowers electricity costs.

- • Sustainability:

- o Optimized systems consume less energy and reduce environmental impact.

- o Minimizes waste of refrigerated products due to system failures.

- 4. Regulatory Compliance:

- o Continuous monitoring makes it easier to demonstrate good practices and compliance with food safety and conservation regulations.

How Sensors Monitor Conditions in Real Time

Sensors capture critical system information and transmit it to a central monitoring system or a cloud-based platform. Here are the main operational steps:

- 1. Data Collection:

- o Sensors measure variables such as temperature, pressure, modulation, motor runtime, and energy consumption.

- 2. Real-Time Analysis:

- o Data is processed instantly, allowing for the detection of operational deviations.

- 3. Alert Generation:

- o In case of irregularities, the system issues alerts so that the technical team can take necessary actions.

- 4. Integration with Automation:

- o In advanced systems, sensors can trigger automatic adjustments, such as temperature regulation or thermal load redistribution.

Examples of Sensors Used in Refrigeration and Air Conditioning Systems

- 1. Temperature Sensors:

- o Monitor and maintain the proper temperature for food preservation.

- They detect overheating or variations that may compromise the quality of the products.

- 2. Pressure Sensors:

- o Ensure the system operates under ideal conditions, preventing compressor damage and maintaining energy efficiency.

- 3. Vibration Sensors:

- o Detect mechanical failures, such as bearing wear or component misalignment.

- 4. Airflow Sensors:

- o Evaluate air circulation to prevent blockages or thermal distribution issues.

- Energy Sensors:

- o Measure electrical consumption and help identify underperforming equipment.

Conclusion

The integration of sensors in refrigeration and air conditioning systems is transforming supermarket management. With continuous monitoring, it is possible to enhance efficiency, reduce costs, and improve sustainability. Additionally, these advancements help ensure food safety and customer comfort.

Ready to optimize your supermarket’s maintenance? Click here and Discover how NEO Estech and CBM can transform your operations and deliver sustainable results!